The Benefits Of Infrared Cameras Phase 1 Blog Machine Vision Blog

The Benefits Of Infrared Cameras Phase 1 Blog Machine Vision Blog The benefits of infrared imaging cameras. first and foremost, the biggest benefit of infrared cameras is their ability to operate in low light conditions where cameras with normal ccd or cmos sensors would struggle. this is particularly useful for security and surveillance, as night time conditions have no impact on the amount of energy an. Lwir cameras capture light in the 8 14 μm spectral band. this is opposed to short wave infrared cameras that operate in the 0.9 1.7 μm spectral band, and medium wave infrared cameras that operate in the 3 5 μm spectral band. typically, lwir cameras leverage a bolometer or microbolometer as an image sensor.

The Use Of Lwir Cameras For Industrial Thermal Imaging Machine Vision For the most part, swir inspection systems operate in much the same way that visible systems do: a target, a light source, and a detector capture the image. swir cameras are often built around indium gallium arsenide (ingaas) based infrared detectors, which can be extremely sensitive. as a result, swir cameras work well in light starved conditions. Imaging beyond the visible. one such non visible spectral band is the short wave infrared (swir) band (defined here as 750 2600nm). many materials that appear similar in the visible spectrum, look very different in swir. figure 1 shows 4 different liquids (water, acetone, tce, and isopropyl alcohol). Infrared imaging based machine vision (irmv) is the technology used to automatically inspect, detect, and analyse infrared images (or infrared videos) obtained by recording the intensity of ir light emitted or reflected by observed objects. an alternative definition of irmv is the ability of machines to create images by infrared (ir) rays. Cons. one of the most significant downsides to using point and shoot cameras is their small sensor size and even smaller pixels. these small pixels have higher noise levels and smaller maximum true resolution. infrared photography can have increased noise, which will be much more noticeable with a point and shoot camera.

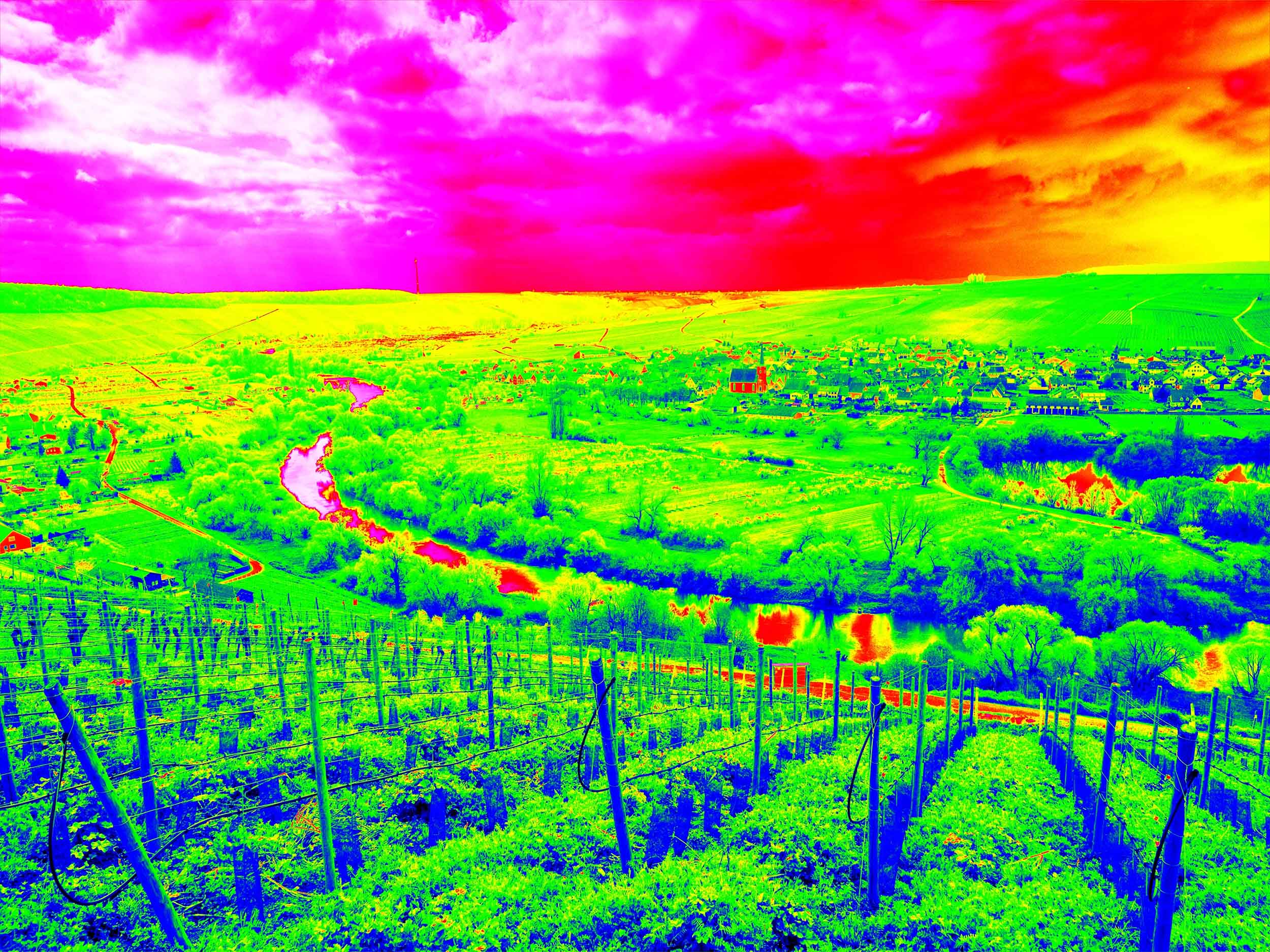

Multispectral Imaging Applications Outdoors Machine Vision Blog Infrared imaging based machine vision (irmv) is the technology used to automatically inspect, detect, and analyse infrared images (or infrared videos) obtained by recording the intensity of ir light emitted or reflected by observed objects. an alternative definition of irmv is the ability of machines to create images by infrared (ir) rays. Cons. one of the most significant downsides to using point and shoot cameras is their small sensor size and even smaller pixels. these small pixels have higher noise levels and smaller maximum true resolution. infrared photography can have increased noise, which will be much more noticeable with a point and shoot camera. By selecting a camera with a sensor recommended for nir wavelengths, i.e. sony pregius and starvis, and applying gain, you will end up with a much clearer image than relying on qe values alone. machine vision solutions for non visible imaging from clearview imaging. that’s it for this week’s blog post on near infrared (nir) imaging. Posted on april 30, 2019. shortwave infrared (swir) imaging introduces a broad range of possibilities in industrial and scientific applications. traditional machine vision systems using ccd and cmos image sensors can effectively capture images within the visible spectrum of light. but vision systems leveraging swir technology can capture images.

Applications That Depend On Ir Cameras For Effective Performance By selecting a camera with a sensor recommended for nir wavelengths, i.e. sony pregius and starvis, and applying gain, you will end up with a much clearer image than relying on qe values alone. machine vision solutions for non visible imaging from clearview imaging. that’s it for this week’s blog post on near infrared (nir) imaging. Posted on april 30, 2019. shortwave infrared (swir) imaging introduces a broad range of possibilities in industrial and scientific applications. traditional machine vision systems using ccd and cmos image sensors can effectively capture images within the visible spectrum of light. but vision systems leveraging swir technology can capture images.

Comments are closed.