The Complete Guide To Laser Powder Bed Fusion In 3d Printing 3dnatives

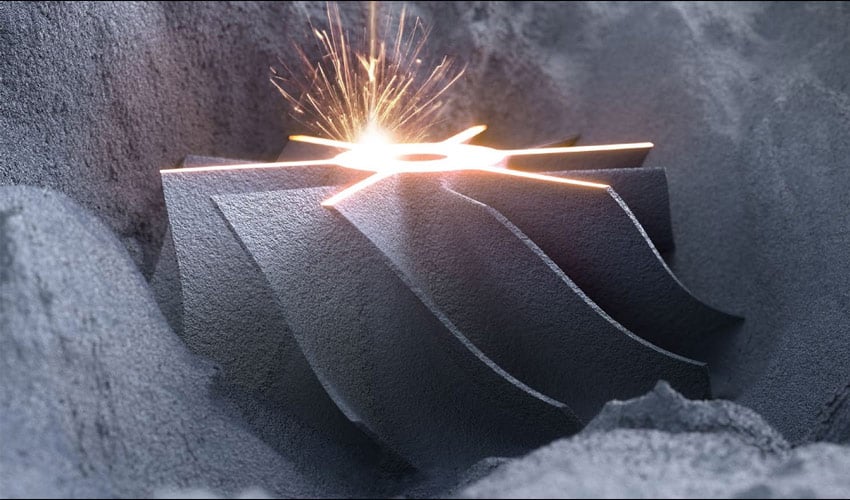

The Complete Guide To Laser Powder Bed Fusion In 3d Printing 3dnatives Published on september 3, 2023 by alexandrea p. laser powder bed fusion is a group of metal additive manufacturing methods that use, as the name suggests, a powder bed and a laser to fuse the powder together. notably, this includes dmls, or direct metal laser sintering, is a metal 3d printing method that is well known for its ability to create. Introduction to powder bed fusion 3d printing the powder bed fusion 3d printer melts and fuses layers of powdered material to produce high precision, three dimensional objects. this innovative technology has revolutionized manufacturing, making it possible to create complex structures with exceptional accuracy and precision.

The Complete Guide To Laser Powder Bed Fusion In 3d Printing 3dnatives The complete guide to laser powder bed fusion in 3d printing published on september 3, 2023 by alexandrea p. laser powder bed fusion is a group of metal additive manufacturing methods that use, as the name suggests, a powder bed and a laser to fuse the powder together. Electron beam melting (ebm) is part of the powder bed fusion family. unlike laser powder bed fusion (lpbf), it uses, as its name suggests, an electron beam to fuse metal particles and create, layer by layer, the desired part. marketed by the swedish company arcam in 2002, this process enables the creation of complex and highly resistant structures. Powder bed fusion 3d printing (pbf) – the ultimate guide. by all3dp. published jul 31, 2023. using energy to fuse a bed of powder material into solid, intricate shapes is one of the most popular types of 3d printing. learn how it works and which solution is right for you. To start the process and prepare the 3d sls printer, the powder hopper and the construction area are heated below the melting temperature of the polymer powder (1). the first layer of powder is deposited onto the construction platform (2). then, a co2 laser selectively sinters (i.e. fuses) the powdered polymer particles in the shape desired.

Comments are closed.