Using Ecm Smart Circulator Pumps In Primary Pump Applications

Using Ecm Smart Circulator Pumps In Primary Pump Applications Using b&g ecocirc ® xl ecm smart circulator pumps in primary hydronic systems. these function in two different ways, though the application is identical: most receive a 0 10v signal from the boilers indicating what speed the boiler wants the pump to run (laars vari prime, for example). the boiler itself is determining this speed based on the. The system today exceeds this seemingly implausible goal, drawing just one fifth of that 300 watt target – 57 watts – thanks to a revolutionary new ecm circulator from grundfos pumps. first introduced by grundfos in europe roughly a decade ago, the alpha™ is an energy optimized, 115 volt circulator that automatically and continuously.

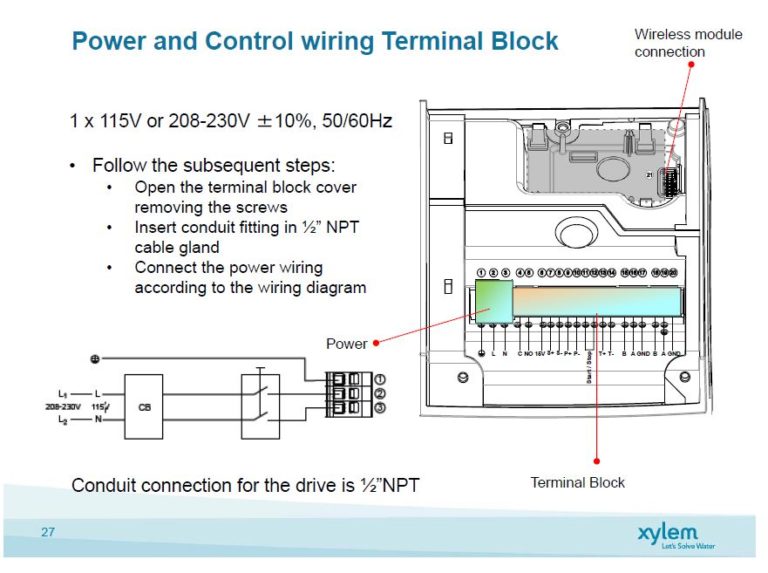

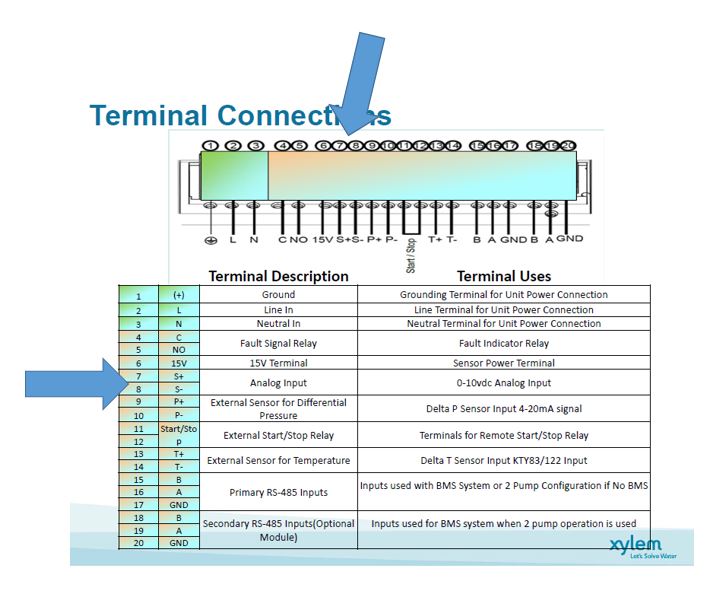

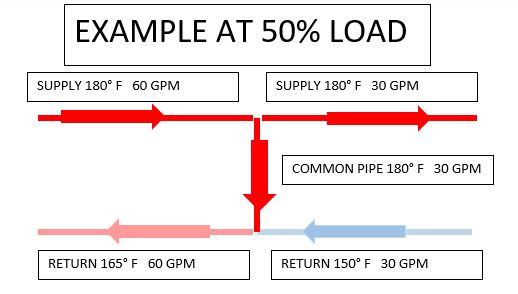

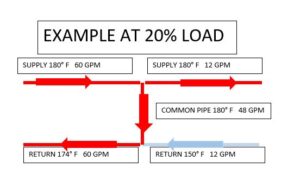

Using Ecm Smart Circulator Pumps In Primary Pump Applications Users can measure energy consumption and usage on a competitive pump basis based on individual pumps’ specific hi rating — the higher the energy rating, the more efficient the pump. ecm technology in hvac applications can decrease energy usage by as much as 75%. for example, a standard efficiency circulator has a typical er of 48 to 50. This primary secondary application uses the b&g ecocirc xl in a sensorless variable speed application. the ecm ecocirc xl has a proportional pressure (Δp) mode, which will sense the kilowatt (kw) usage as well as the speed of the pump and reduce the speed as the two way valves start to close. the pump will slow down by following a straight. Electrical diagrams and control sequence for ecm smart circulator pumps with three way valves. electrical diagram is the same as other applications. sequence of operation. primary heating cooling pump (insert tag) shall be enabled by a call for heat cool (enabling the start stop contacts 11 12 through a remote relay). the pump speed shall be. The most efficient circulators. there are many ways to improve the efficiency of a pump. powered by electronically commutated motors (ecm), the upse and alpha feature optimized hydraulics, multiple control modes, and the highest hydraulic institute energy rating in the market. together, these features make the upse and alpha the most efficient.

Using Ecm Smart Circulator Pumps In Primary Pump Applications Electrical diagrams and control sequence for ecm smart circulator pumps with three way valves. electrical diagram is the same as other applications. sequence of operation. primary heating cooling pump (insert tag) shall be enabled by a call for heat cool (enabling the start stop contacts 11 12 through a remote relay). the pump speed shall be. The most efficient circulators. there are many ways to improve the efficiency of a pump. powered by electronically commutated motors (ecm), the upse and alpha feature optimized hydraulics, multiple control modes, and the highest hydraulic institute energy rating in the market. together, these features make the upse and alpha the most efficient. The application dictates delta t or delta p control. the bottom line is changing flow and maintaining it smartly, exactly as dictated by demand. today, pumps and circulators can get the gift of this intelligence as a retrofit improvement. or, even better, new smart pumps are “born” with the brains to meet system needs precisely. reference. The united states department of energy (doe) recently proposed new energy conservation standards for circulator pumps, prompting manufacturers to design them for increased efficiency. circulator pumps are ubiquitous, and the opportunity to reduce their energy consumption is enormous. an electric power research institute (epri) report estimated the energy savings potential for the approximately.

Using Ecm Smart Circulator Pumps In Primary Pump Applications The application dictates delta t or delta p control. the bottom line is changing flow and maintaining it smartly, exactly as dictated by demand. today, pumps and circulators can get the gift of this intelligence as a retrofit improvement. or, even better, new smart pumps are “born” with the brains to meet system needs precisely. reference. The united states department of energy (doe) recently proposed new energy conservation standards for circulator pumps, prompting manufacturers to design them for increased efficiency. circulator pumps are ubiquitous, and the opportunity to reduce their energy consumption is enormous. an electric power research institute (epri) report estimated the energy savings potential for the approximately.

Using Ecm Smart Circulator Pumps In Primary Pump Applications

Comments are closed.