What Is Plastic Injection Mold Structure

Structure Of Injection Mold Topworks Plastic Mold A comprehensive introduction to injection mold components and the structure from a 20 year experienced expert from a big mold making factory. In the world of manufacturing, injection molding is a widely used process for producing high quality plastic parts in large quantities. at the heart of this process lies the injection mold structure, which plays a crucial role in determining the success and efficiency of the entire production cycle. 2. components of an injection mold. a. mold base.

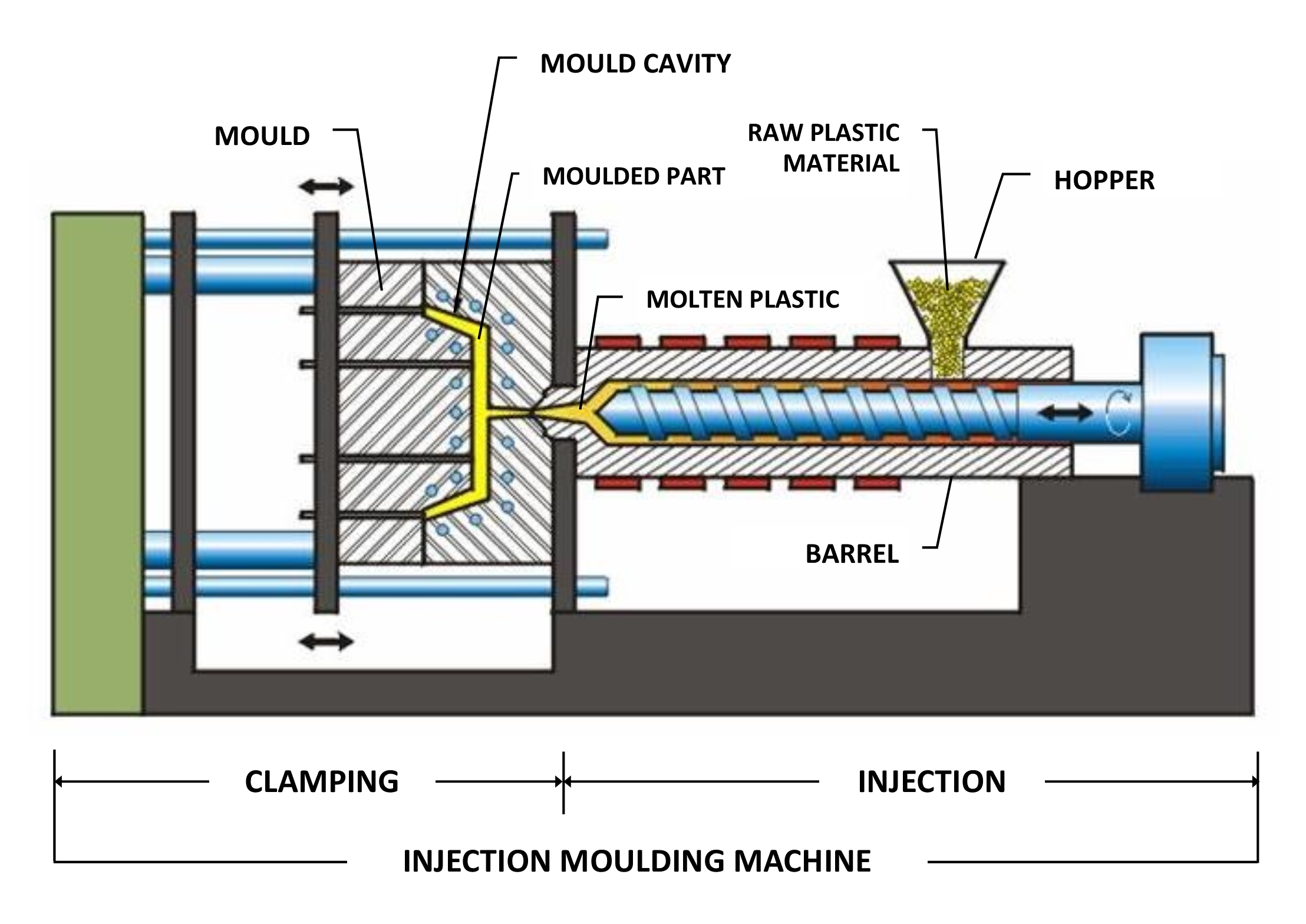

One Picture To Understand The Structure Of An Injection Mold Injection molding is a complex manufacturing process. using a specialized hydraulic or electric machine, the process melts, injects and sets plastic into the shape of a metal mold that’s fitted into the machine. plastic injection molding is the most widely used components manufacturing process for a variety of reasons, including: flexibility. A plastic injection mold is a complex assembly of several components designed to create a desired plastic product. the main components of a typical injection mold structure are: mold base this is the main structure that holds all other mold components together. it is usually made of steel and provides support, alignment, and guidance for […]. Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Step 3: injection molding machine operation. once the mold is ready and material selected, the machine comes into play. plastic pellets are heated to their melting point in a hopper. the molten plastic is then injected into the mold cavity at high pressure, typically between 10,000 to 30,000 psi.

Robotics In Injection Moulding Rna Automation Injection molding is a manufacturing technology for the mass production of identical plastic parts with good tolerances. in injection molding, polymer granules are first melted and then injected under pressure into a mold, where the liquid plastic cools and solidifies. the materials used in injection molding are thermoplastic polymers that can. Step 3: injection molding machine operation. once the mold is ready and material selected, the machine comes into play. plastic pellets are heated to their melting point in a hopper. the molten plastic is then injected into the mold cavity at high pressure, typically between 10,000 to 30,000 psi. The injection molding cycle works by this continuous process—closing the mold, feeding heating the plastic granules, pressurizing them into the mold, cooling them into a solid part, ejecting the part, and closing the mold again. this system allows for the rapid production of plastic parts, and upwards of 10,000 plastic parts can be made in a. This begins the material’s journey. the barrel heats and melts the plastic. friction and barrel heaters melt the pellets at 200 300°c. an internal screw mixes the polymer. the screw injects the molten plastic. the rotating screw provides consistent pressure and speed for complete mold filling. the two mold halves close.

Comments are closed.