Why Going Straight From Prototypes To Mass Production Is Dangerous

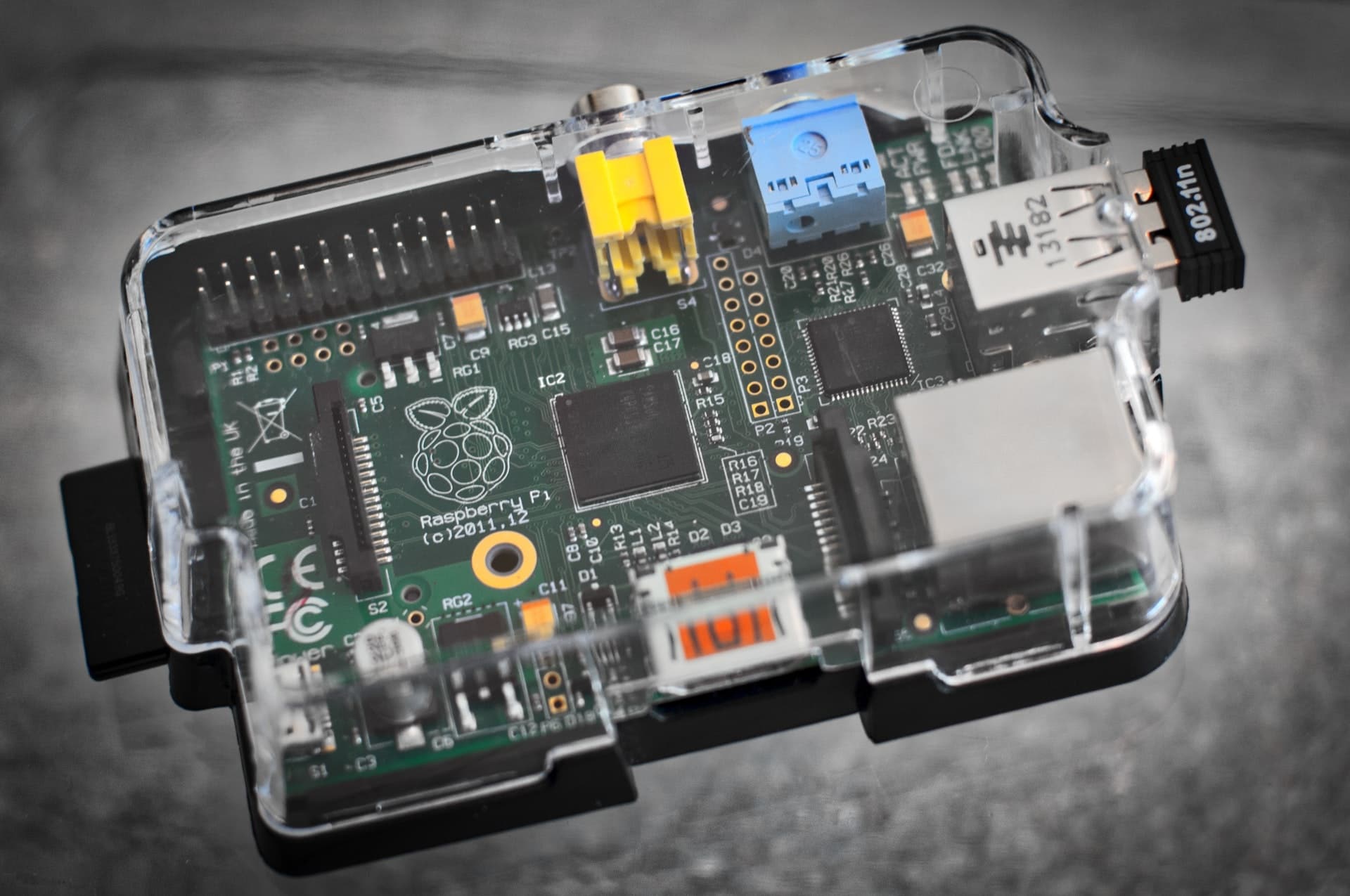

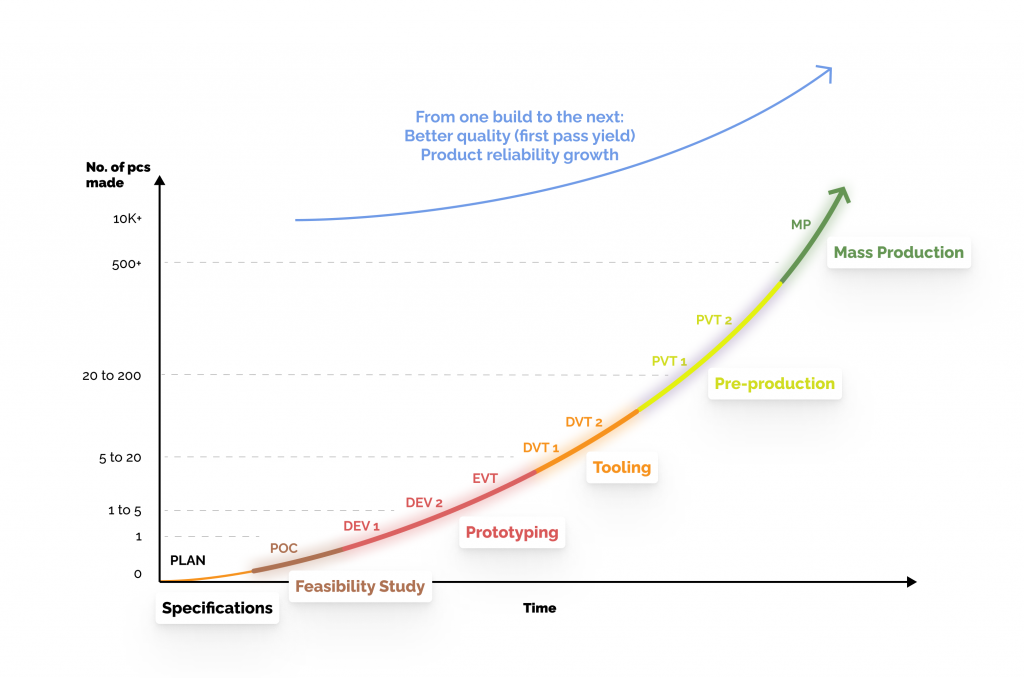

Why Going Straight From Prototypes To Mass Production Is Dangerous Early prototypes, when the mechanical and electronic engineers are working, can be made 1 or 2 at a time. when prototypes get closer to final approval, they might have to be made in larger numbers to allow for more testing. at this stage, it is user testing and accelerated reliability & durability testing (to find what the weaknesses are). A centralized platform that connects your team, contractors, and suppliers is your solution. openbom is a cloud based platform to manage your engineering and manufacturing data. companies from startups to fortune 500’s use openbom to create a centralized database to bring in, store and manage their manufacturing data.

Going From 1 Prototype To Mass Production Directly Is Dangerous Conclusion. scaling a product from prototype to mass manufacturing is a complex journey. yet, with the right understanding and preparation, it’s a journey that can lead to remarkable rewards. as stanford’s doerr school of sustainability highlights, thinking about scale from the beginning and understanding the risks and barriers associated. Unfortunately, many people think having a prototype is the final step before launching mass production. and, for electronic and or mechanical products, that’s a dangerous misconception. let’s examine each pitfall that can badly affect your plans to go from prototype to production smoothly here: 1. confirming a product design that is not. Logan from rokblok, featured on shark tank season 9, illustrates the challenges and triumphs of transitioning an existing prototype to mass production. after gaining significant exposure and a surge in orders from the show, rokblok faced a crucial issue: 7% of the product was found to be defective. Efficiency and scalability are crucial factors in the successful transition from prototype to mass production. streamlining production processes involves optimizing workflows, reducing waste, and maximizing productivity. when you are planning production nothing tends to go right the first time. oftentimes bottlenecks can slow down a particular.

Going From 1 Prototype To Mass Production Directly Is Dangerous Logan from rokblok, featured on shark tank season 9, illustrates the challenges and triumphs of transitioning an existing prototype to mass production. after gaining significant exposure and a surge in orders from the show, rokblok faced a crucial issue: 7% of the product was found to be defective. Efficiency and scalability are crucial factors in the successful transition from prototype to mass production. streamlining production processes involves optimizing workflows, reducing waste, and maximizing productivity. when you are planning production nothing tends to go right the first time. oftentimes bottlenecks can slow down a particular. The scaling phase begins once you have the custom production quality prototype. time from prototype to mass manufacturing. i typically find the time required to go from idea to final prototype is similar to the time it takes to go from prototype all the way to mass manufacturing. so once you have your production quality prototype you are. Table of contents: step 1 make sure your design is ready for manufacturing. step 2 source contract manufacturers and request for quote. step 3 conduct an audit. step 4 supplier agreement and pricing negotiations. step 5 pilot run. step 6 certification and product performance testing. step 7 mass production.

Prototype Vs Production 5 Crucial Differences In Manufacturing The scaling phase begins once you have the custom production quality prototype. time from prototype to mass manufacturing. i typically find the time required to go from idea to final prototype is similar to the time it takes to go from prototype all the way to mass manufacturing. so once you have your production quality prototype you are. Table of contents: step 1 make sure your design is ready for manufacturing. step 2 source contract manufacturers and request for quote. step 3 conduct an audit. step 4 supplier agreement and pricing negotiations. step 5 pilot run. step 6 certification and product performance testing. step 7 mass production.

How Additive Speeds Up Time From Prototyping To Mass Production

Comments are closed.